一、 Features: 性能特點

1、采用國內新型的大傳動機構,由排鏈帶動主傳動軸,免除了其它齒輪傳動的誤差和噪音。

It adopts the newest type high-power transmission mechanism to arrange

the chain and drive the main driving shaft. The errors and noises of other gear

wheel transmission can be avoided.

2、電器采用進口控制系統,便可按照客戶要求,配置缺料漏補裝置和缺粒檢測剔除裝置。

Imported controlling system is adopted; also it can be equipped with

detecting and rejection function device for number of medicines according to

the user’s requirement.

3、采用光電控制系統,PVC、PTP、硬鋁包裝自動送料、廢邊自動沖切裝置,確保超長距離多工位同步穩定性。

It adopts

photoelectrical controlling system to make PVC, PTP, Aluminum/Aluminum material

to be automatically fed and waste side to be cut automatically to guarantee the

Synchronous stability of over- length distance and multi stations.

4、可另配光電檢測校正裝置,配進口步進電機牽引,圖文對版印刷包裝,優化包裝物檔次。

It can be

optional equipped with photocell correction device, imported stepper motor

traction and image- character register to optimize packing grade.

5、本機適用行業:食品、藥品、醫療器械、五金、電子泡罩密封包裝。

The machine is suitable for industries of foodstuff,

medicine, medical instruments, hardware, electronics and etc for packing.

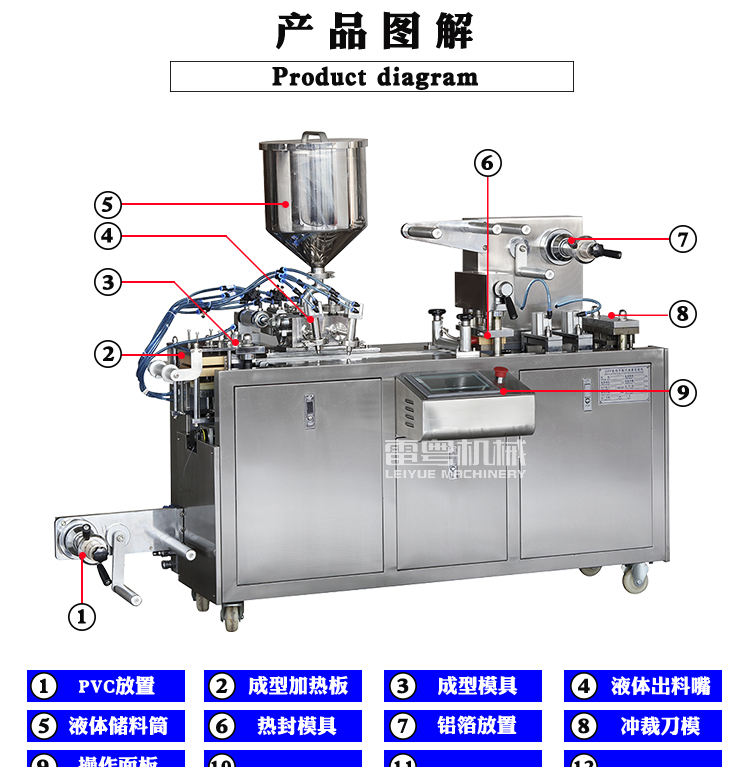

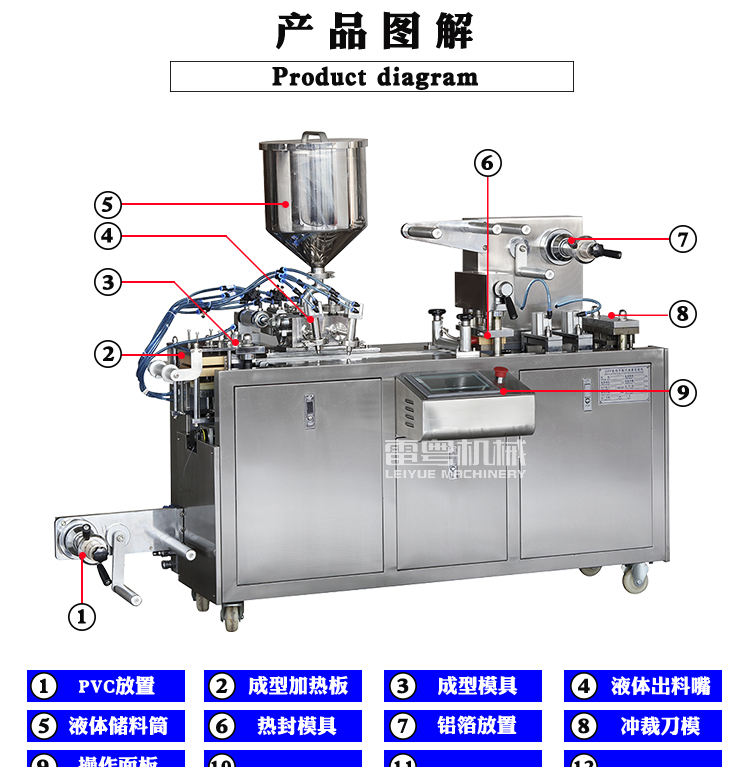

三:布置圖

四:技術參數 Technical Specification

|

型號

Model

|

DPP-80/120

|

|

沖裁次數

Punch frequency

|

10-33次/分

10-33times/min

|

|

生產能力

Production capacity

|

1000-1920版/時

1000-1920plates/hour

|

|

{zd0}成型面積及深度

Max. Forming area & Depth

|

80:110x70(標準深度≦15)(mm){zd0}深度25mm(定制二次成型)

120:130x70(標準深度≦15)(mm){zd0}深度25mm(定制二次成型)

|

|

標準行程范圍

Standard Stroke range

|

30-80毫米( 可按客戶要求設計 )

30-80mm(can be designed as per

user’s required)

|

|

空氣壓力

Air pressure

|

0.4-0.6兆帕

0.4-0.6Mpa

|

|

耗氣量

Compressed air required

|

(空壓機)≥0.3m3/min

Air compressor≥0.3m3/min

|

|

電源總功率

Total power supply

|

220V 50Hz

2.4Kw

|

|

主電極功率

Main motor

|

0.75Kw

|

|

PVC硬片

PVC hard Film

|

0.15-0.5*110毫米(mm)

|

|

PTP鋁箔

PTP Aluminum film

|

0.02-0.035*110毫米(mm)

|

|

透析紙

Dialysis

Paper

|

50-100g*110毫米(mm)

|

|

模具冷卻

Mould cooling

|

自來水或循環水

Tap water or Recycling water

|

|

外型尺寸

Overall Dimension

|

1840x590x1100毫米(mm)(LxWxH)

|

|

重量

Weight

|

凈重415千克(Kg)毛重 465(kg)

Net 415kg Gross weight: 465kg

|

|

噪聲指標

Noise index

|

<75dBA

|

五:工作流程

Work

process

1、成型(上下加熱)

Forming ( up and down heating)

2、熱封(上加熱)

Heating

Sealing ( up heating)

3、打碼

Embossing

4、壓痕(可微量加熱)

Impression

5、切刀

Cutter

6、成型輸出成品

Finished product outp