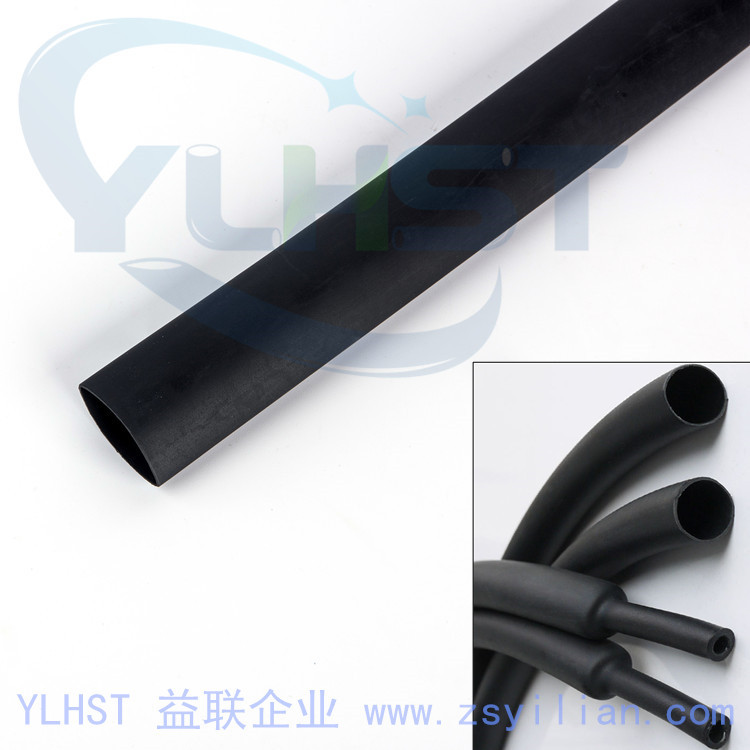

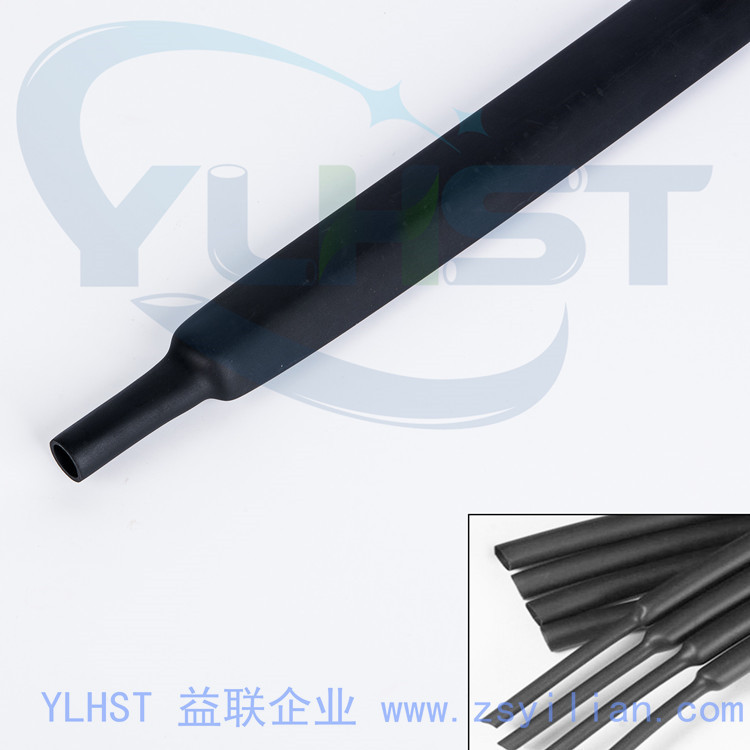

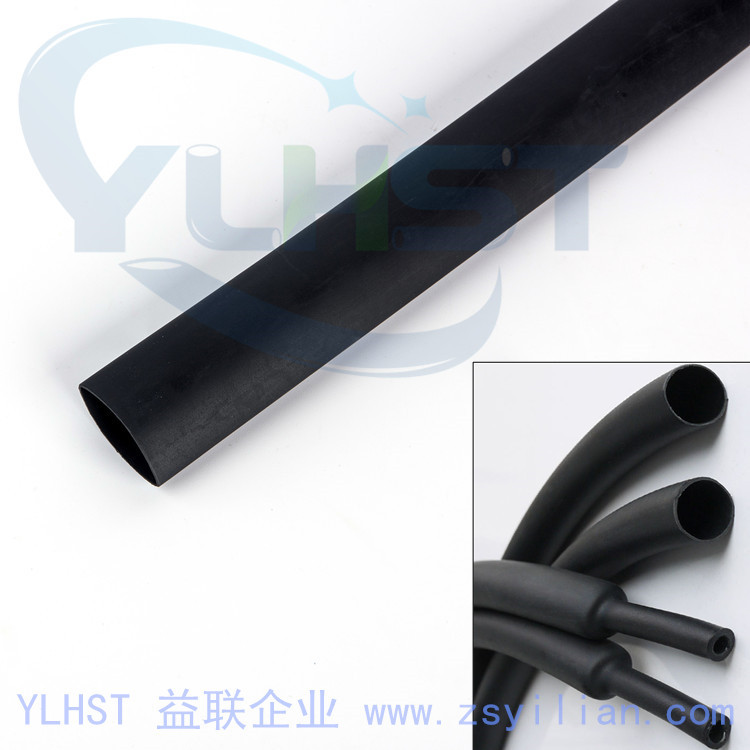

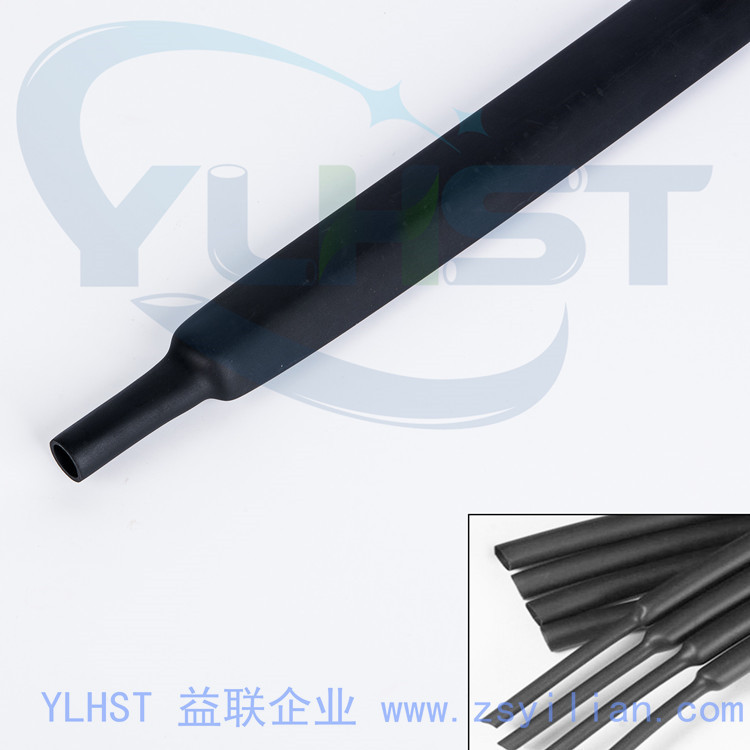

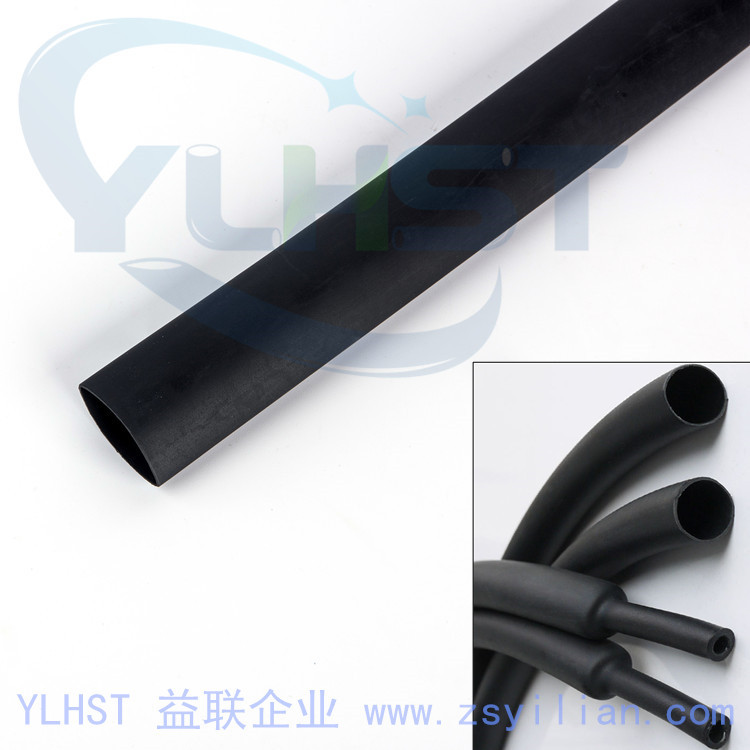

NT120 耐油柔軟氯丁橡膠熱縮管

應(yīng)用

由輻照交聯(lián)優(yōu)質(zhì)耐油氯丁橡膠材質(zhì)制成,柔軟性很好,具有優(yōu)異的耐油、耐化學(xué)腐蝕和耐溶劑性能,適合應(yīng)用于需要耐燃油、耐潤(rùn)滑油、耐磨的環(huán)境,保護(hù)包覆的線束、線纜或被覆元器件免受損傷,廣泛應(yīng)用于商業(yè)、軍事和航空航天業(yè)領(lǐng)域的電纜線束的絕緣、應(yīng)力xc、防摩擦保護(hù)等。

特性

v 收縮比:2:1

v 低溫下仍保持彈性

v 優(yōu)異的耐燃油、耐潤(rùn)滑油、耐化學(xué)腐蝕性能

v 優(yōu)異的耐磨性能

v 非常柔軟、阻燃

v 符合ROHS/REACH環(huán)保規(guī)范

顏色

v 標(biāo)準(zhǔn)顏色:黑色

操作溫度范圍

v 連續(xù)使用溫度范圍:-70℃~121℃

v {zd1}起始收縮溫度:90℃

v {zd1}wq收縮溫度:135℃

符合標(biāo)準(zhǔn)

v SAE AMS-DTL-23053/1,Class 1&2

性能指標(biāo)

|

性能

|

指標(biāo)要求

|

測(cè)試方法

|

典型值

|

|

縱向收縮率

|

≤10%

|

ASTM D 2671

|

≤5%

|

|

抗張強(qiáng)度

|

10.3MPa min

|

ASTM D 638

|

≥11MPa

|

|

斷裂伸長(zhǎng)率

|

225% min

|

ASTM D 638

|

≥300%

|

|

老化后抗張強(qiáng)度

(熱老化121℃,168小時(shí))

|

8.2MPa min

|

ASTM D 638

|

≥10.4MPa

|

|

老化后斷裂伸長(zhǎng)率(121℃,168hrs)

|

175% min

|

ASTM D 638

|

≥200%

|

|

熱沖擊

(150℃,4小時(shí))

|

無(wú)裂紋

|

ASTM D 2671

|

無(wú)裂紋

|

|

低溫柔軟性

(-70℃,4小時(shí))

|

無(wú)裂紋

|

ASTM D 2671

|

無(wú)裂紋

|

|

絕緣耐壓和擊穿

|

2000V,60sec,不擊穿

|

ASTM D 2671

|

不擊穿

|

|

擊穿強(qiáng)度

|

11.8 KV/mm min

|

ASTM D 2671

|

≥15KV/mm

|

|

體積電阻率

|

1011??cm min

|

ASTM D 876

|

≥1011??cm

|

|

腐蝕性

|

無(wú)腐蝕

|

ASTM D 2671

|

無(wú)腐蝕

|

|

阻燃性

|

15分鐘內(nèi)自熄

|

ASTM D 2671

|

通過(guò)

|

|

耐液性(23℃,24hrs)

|

|

抗張強(qiáng)度

|

6.9MPa min

|

ASTM D 638

|

≥9.0MPa

|

|

斷裂伸長(zhǎng)率

|

175% min

|

ASTM D 638

|

≥200%

|

|

擊穿強(qiáng)度

|

9.8 KV/mm min

|

ASTM D 2671

|

≥12KV/mm

|

規(guī)格尺寸

|

規(guī)格

|

收縮前(mm)

|

收縮后(mm)

|

標(biāo)準(zhǔn)包裝

(m/卷)

|

|

英制

|

公制

|

內(nèi)徑(min)

|

內(nèi)徑(max)

|

壁厚

|

|

3/32

|

Ф2.4

|

2.4

|

1.2

|

0.51+0.15

|

200

|

|

1/8

|

Ф3.2

|

3.2

|

1.6

|

0.69+0.20

|

100

|

|

3/16

|

Ф4.8

|

4.8

|

2.5

|

0.84+0.25

|

100

|

|

1/4

|

Ф6.4

|

6.4

|

3.6

|

0.88+0.25

|

100

|

|

3/8

|

Ф9.5

|

9.5

|

5.4

|

1.02+0.25

|

50

|

|

1/2

|

Ф12.7

|

12.7

|

7.3

|

1.21+0.38

|

50

|

|

5/8

|

Ф15.9

|

15.9

|

9.1

|

1.32+0.38

|

50

|

|

3/4

|

Ф19.1

|

19.1

|

10.9

|

1.44+0.38

|

30

|

|

7/8

|

Ф22.2

|

22.2

|

12.7

|

1.65+0.38

|

30

|

|

1

|

Ф25.4

|

25.4

|

14.5

|

1.78+0.50

|

30

|

|

11/4

|

Ф31.8

|

31.8

|

18.1

|

2.20+0.50

|

30

|

|

11/2

|

Ф38.1

|

38.1

|

21.8

|

2.41+0.50

|

30

|

|

2

|

Ф50.8

|

50.8

|

29.0

|

2.79+0.50

|

25

|

其他規(guī)格尺寸可定制

NT120 Diesel Resistance Neoprene Heat Shrinkable Tubing

Application

It is made of irradiation cross-linked flexible neoprene rubber. It is very flexible, excellent resistance to diesel, fluids and solvents. Particularly suitable applied to resistance of diesel fuels, hydraulic fluids, lubrication oils, and abrasion resistance. Widely used for insulation, strain relief, and abrasion protection on cable harnesses and wire bundles in the commercial military and aerospace industries.

Characteristics

v Shrink ratio: 2:1

v Remain flexible at temperature as low as -70℃

v Excellent resistance to oils, aviation and ground vehicle fuels, lubricating oil and hydraulic fluids.

v Excellent abrasion resistance

v Very flexible, flame-resistance.

v ROHS and REACH compliant

Color

v Standard color: Black

Operating Temperature Range

v Operating temperature: -70℃~121℃

v Minimum shrink temperature: 90℃

v Minimum fully recovery temperature: 135℃

Approvals

v SAE AMS-DTL-23053/1,Class 1&2

Property

|

Property

|

Requirement

|

Test method

|

Typical data

|

|

Longitudinal shrinkage

|

≤10%

|

ASTM D 2671

|

≤5%

|

|

Tensile strength

|

10.3MPa min

|

ASTM D 638

|

≥11MPa

|

|

Elongation at break

|

225% min

|

ASTM D 638

|

≥300%

|

|

Tensile strength after aging

(121℃,168hrs)

|

8.2MPa min

|

ASTM D 638

|

≥10.4MPa

|

|

Elongation after aging

(121℃,168hrs)

|

175% min

|

ASTM D 638

|

≥200%

|

|

Heat shock

|

No crack

|

ASTM D 2671

|

No crack

|

|

Low-temperature flexibility(150℃,4hrs)

|

No crack

|

ASTM D 2671

|

No crack

|

|

Dielectric voltage withstand

|

2000V,60sec,no breakdown

|

ASTM D 2671

|

No breakdown

|

|

Dielectric strength

|

11.8 KV/mm min

|

ASTM D 2671

|

≥15KV/mm

|

|

Volume resistivity

|

1011??cm min

|

ASTM D 876

|

≥1011??cm

|

|

Copper corrosion

|

No corrosion

|

ASTM D 2671

|

No corrosion

|

|

Flammability

|

Self-extinguishing within 15s

|

ASTM D 2671

|

Pass

|

|

Fluids resistance(23℃,24hrs)

|

|

Tensile strength

|

6.9MPa min

|

ASTM D 638

|

≥9.0MPa

|

|

Elongation at break

|

175% min

|

ASTM D 638

|

≥200%

|

|

Dielectric strength

|

9.8 KV/mm min

|

ASTM D 2671

|

≥12KV/mm

|

Sizes

|

Size

|

As supplied (mm)

|

After recovered(mm)

|

Standard packing

(m/roll)

|

|

inch

|

mm

|

Inside diameter(min)

|

Inside diameter max

|

Wall thickness

|

|

3/32

|

Ф2.4

|

2.4

|

1.2

|

0.51+0.15

|

200

|

|

1/8

|

Ф3.2

|

3.2

|

1.6

|

0.69+0.20

|

100

|

|

3/16

|

Ф4.8

|

4.8

|

2.5

|

0.84+0.25

|

100

|

|

1/4

|

Ф6.4

|

6.4

|

3.6

|

0.88+0.25

|

100

|

|

3/8

|

Ф9.5

|

9.5

|

5.4

|

1.02+0.25

|

50

|

|

1/2

|

Ф12.7

|

12.7

|

7.3

|

1.21+0.38

|

50

|

|

5/8

|

Ф15.9

|

15.9

|

9.1

|

1.32+0.38

|

50

|

|

3/4

|

Ф19.1

|

19.1

|

10.9

|

1.44+0.38

|

30

|

|

7/8

|

Ф22.2

|

22.2

|

12.7

|

1.65+0.38

|

30

|

|

1

|

Ф25.4

|

25.4

|

14.5

|

1.78+0.50

|

30

|

|

11/4

|

Ф31.8

|

31.8

|

18.1

|

2.20+0.50

|

30

|

|

11/2

|

Ф38.1

|

38.1

|

21.8

|

2.41+0.50

|

30

|

|

2

|

Ф50.8

|

50.8

|

29.0

|

2.79+0.50

|

25

|

Other sizes are available upon request.