應用

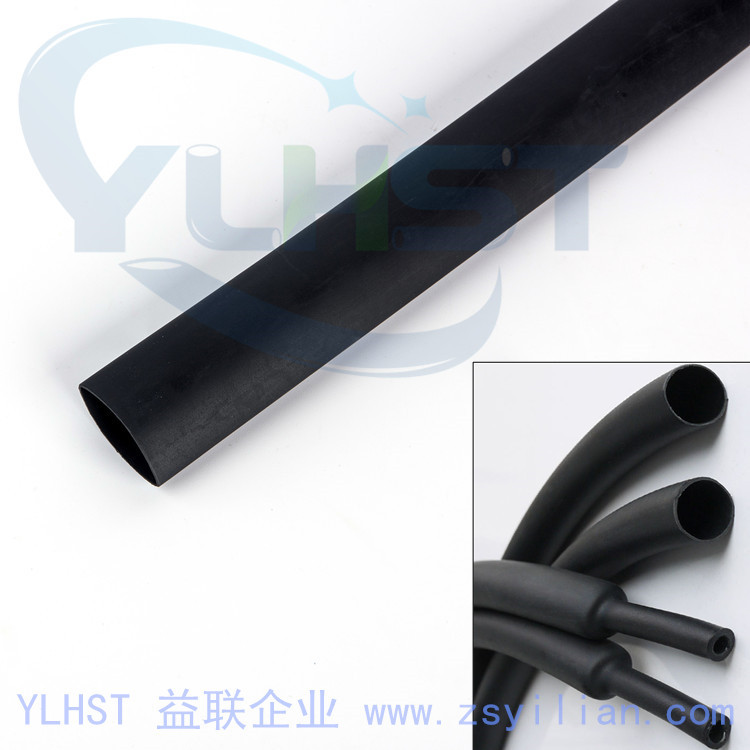

K-135是一種高質量的通用型熱縮管,由輻射交聯優質耐溫135℃柔軟聚烯烴材質制成,具有優異的電氣性能、物理性能肯化學性能,廣泛應用于商用、jy領域中的線束、線纜或被覆元器件的絕緣保護、包覆或標識等。

特性

? 收縮比2:1,3:1

? 優異的電絕緣性能、物理性能和化學性能

? 柔軟、高阻燃

? 符合ROHS.REACH環保規范

顏色

? 標準顏色:黑色、白色、紅色、黃色、藍色、綠色、灰色、透明(不阻燃)

? 其他顏色可定制

操作溫度范圍

? 連續使用溫度:-55℃~135℃

? {zd1}起始收縮溫度:70℃

? {zd1}wq收縮溫度:120℃

符合標準

? SAE AMS-DTL-23053/5

? UL224 125℃ 600V VW-1

性能指標

|

性能

|

指標要求

|

測試方法

|

典型值

|

|

縱向收縮率

|

≤10%

|

ASTM D 2671

|

≤5%

|

|

抗張強度

|

10.4MPa min

|

ASTM D 638

|

≥12MPa

|

|

斷裂伸長率

|

200% min

|

ASTM D 638

|

≥400%

|

|

老化后抗張強度

(熱老化175℃,168小時)

|

7.28MPa min

|

ASTM D 638

|

≥10.4MPa

|

|

老化后斷裂伸長率

(熱老化175℃,168小時)

|

100% min

|

ASTM D 638

|

≥300%

|

|

熱沖擊

(250℃,4小時)

|

無裂紋

|

ASTM D 2671

|

無裂紋

|

|

低溫柔軟性

(-55℃,4小時)

|

無裂紋

|

ASTM D 2671

|

無裂紋

|

|

絕緣耐壓和擊穿

|

2500V,60sec,不擊穿

|

ASTM D 2671

|

不擊穿

|

|

擊穿強度

|

19.7KV/mm min

|

ASTM D 2671

|

≥25KV/min

|

|

體積電阻率

|

1014??cm min

|

ASTM D 876

|

≥1014??cm

|

|

腐蝕性

|

無腐蝕

|

ASTM D 2671

|

無腐蝕

|

|

阻燃性

|

VW-1

|

UL224

|

通過

|

規格尺寸

|

規格

|

收縮前(mm)

|

wq收縮后(mm)

|

標準包裝(m/卷)

|

|

英制

|

公制

|

內徑(min)

|

內徑(min)

|

壁厚

|

|

2:1

|

|

3/64

|

Ф1.2

|

1.2

|

0.6

|

0.43+0.08

|

200

|

|

1/16

|

Ф1.6

|

1.6

|

0.8

|

0.43+0.08

|

200

|

|

3/32

|

Ф2.4

|

2.4

|

1.2

|

0.51+0.08

|

200

|

|

1/8

|

Ф3.2

|

3.2

|

1.6

|

0.51+0.08

|

200

|

|

3/16

|

Ф4.8

|

4.8

|

2.4

|

0.64+0.08

|

100

|

|

1/4

|

Ф6.4

|

6.4

|

3.2

|

0.64+0.08

|

100

|

|

5/16

|

Ф8.0

|

8.0

|

4.0

|

0.64+0.08

|

100

|

|

3/8

|

Ф9.5

|

9.5

|

4.8

|

0.64+0.08

|

100

|

|

1/2

|

Ф12.7

|

12.7

|

6.4

|

0.64+0.08

|

100

|

|

5/8

|

Ф16.0

|

16.0

|

8.0

|

0.76+0.08

|

100

|

|

3/4

|

Ф19.1

|

19.1

|

9.5

|

0.76+0.08

|

50

|

|

1

|

Ф25.4

|

25.4

|

12.7

|

0.89+0.12

|

50

|

|

11/4

|

Ф31.8

|

31.8

|

15.9

|

1.02+0.15

|

50

|

|

11/2

|

Ф38.1

|

38.1

|

19.1

|

1.02+0.15

|

50

|

|

2

|

Ф50.8

|

50.8

|

25.4

|

1.14+0.16

|

50

|

|

3:1

|

|

1/16

|

Ф1.6/0.5

|

1.6

|

0.5

|

0.50+0.10

|

200

|

|

3/32

|

Ф2.4/0.8

|

2.4

|

0.8

|

0.50+0.10

|

200

|

|

1/8

|

Ф3.2/1.1

|

3.2

|

1.1

|

0.60+0.10

|

200

|

|

3/16

|

Ф4.8/1.6

|

4.8

|

1.6

|

0.60+0.10

|

100

|

|

1/4

|

Ф6.4/2.1

|

6.4

|

2.1

|

0.70+0.10

|

100

|

|

3/8

|

Ф9.5/3.2

|

9.5

|

3.2

|

0.85+0.15

|

100

|

|

1/2

|

Ф12/4

|

12.0

|

4.0

|

0.85+0.15

|

100

|

|

3/4

|

Ф18/6

|

18.0

|

6.0

|

1.00+0.15

|

50

|

|

1

|

Ф24/8

|

24.0

|

8.0

|

1.20+0.20

|

50

|

|

11/2

|

Ф39/13

|

39.0

|

13.0

|

1.20+0.20

|

50

|

其他規格尺寸可定制。

135℃Heat Resistant Heat-shrinkable Polyolefin Tubing

Application

K-135 is a high -quality general purpose heat-shrinkable tubing made by excellent irriation cross-linked 135℃ flexible polyolefin compound. The product has excellent electrical,physical and chemical properties. Widely used for insulation and strain relief of wire harness, cable and connectors in industry and military fields. And used for jacketing wire bundles and light-duty harnesses where superior abrasion. Also suitable for light-duty harnessing, jacketing, and identification of wires, cables and electrical anc?electronic components.

Characteristics

? Shrink ratio 2:1,3:1

? Excellent electrical, physical and chemical properties.

? Flexible, highly flame-retardant.

? ROHS and REACH compliant.

Color

? Standard color: black, white, red, yellow, blue, green, grey, clear(non flame-retardant)

? Other colors are available upon request.

Operating Temperature Range

? Operating temperature:-55℃~135℃

? Minimum shrink temperature:70℃

? Minimum fully recovery temperature:120℃

Approvals

? SAE AMS-DTL-23053/5

? UL2241250C 600V VW-1

Property

|

Property

|

Requirement

|

Test method

|

Typical data

|

|

Longitudinal shrinkage

|

≤10%

|

ASTM D 2671

|

≤5%

|

|

Tensile strength

|

10.4MPa min

|

ASTM D 638

|

≥12MPa

|

|

Elongation at break

|

200% min

|

ASTM D 638

|

≥400%

|

|

Tensile strength after aging

(175℃,168hrs)

|

7.28MPa min

|

ASTM D 638

|

≥10.4MPa

|

|

Elongation after aging

(175℃,168hrs)

|

100% min

|

ASTM D 638

|

≥300%

|

|

Heat shock

(250℃,4hrs)

|

No crack

|

ASTM D 2671

|

No crack

|

|

Low-temperature flexibility(-55℃,4hrs)

|

No crack

|

ASTM D 2671

|

No crack

|

|

Dielectric voltage withstand

|

2500V,60sec, no breakdown

|

ASTM D 2671

|

No breakdown

|

|

Dielectric strength

|

19.7KV/mm min

|

ASTM D 2671

|

≥25KV/min

|

|

Volume resistivity

|

1014??cm min

|

ASTM D 876

|

≥1014??cm

|

|

Corrosion

|

No corrosion

|

ASTM D 2671

|

No corrosion

|

|

Flammability

|

VW-1

|

UL224

|

Pass

|

Sizes

|

Size

|

As supplied(mm)

|

After recovered(mm)

|

Standard packing

(m/roll)

|

|

Inch

|

mm

|

Inside diameter(mm)

|

Inside diameter(mm)

|

Wall thickness

|

|

2:1

|

|

3/64

|

Ф1.2

|

1.2

|

0.6

|

0.43+0.08

|

200

|

|

1/16

|

Ф1.6

|

1.6

|

0.8

|

0.43+0.08

|

200

|

|

3/32

|

Ф2.4

|

2.4

|

1.2

|

0.51+0.08

|

200

|

|

1/8

|

Ф3.2

|

3.2

|

1.6

|

0.51+0.08

|

200

|

|

3/16

|

Ф4.8

|

4.8

|

2.4

|

0.64+0.08

|

100

|

|

1/4

|

Ф6.4

|

6.4

|

3.2

|

0.64+0.08

|

100

|

|

5/16

|

Ф8.0

|

8.0

|

4.0

|

0.64+0.08

|

100

|