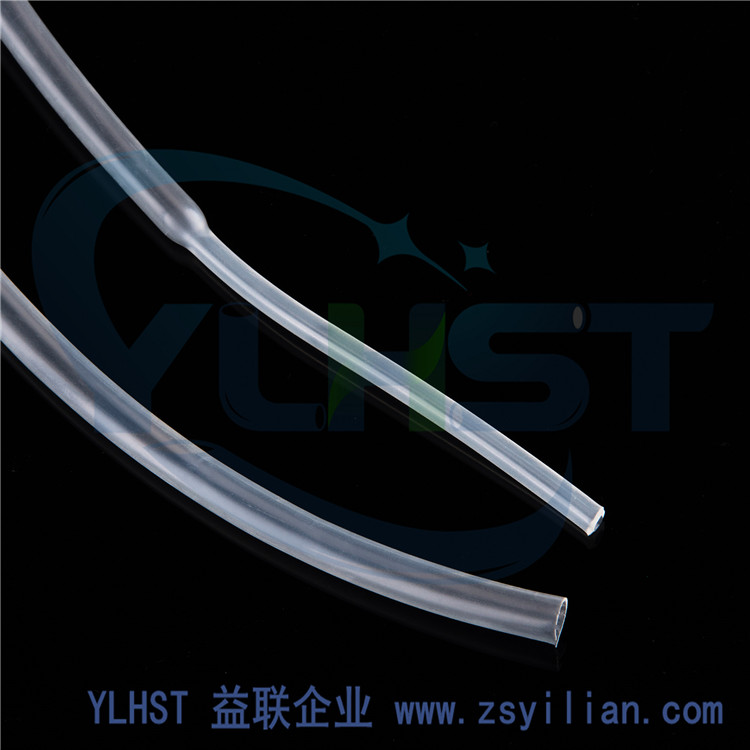

DW125 柔軟高倍雙壁熱收縮套管

應(yīng)用

由聚烯烴和熱熔膠共擠制造而成,用于需要密封防水防潮的電線電纜、配線和連接器的絕緣保護(hù),可以很好地應(yīng)用于電子電器、汽車(chē)和通訊等很多行業(yè)中。

特性

? 優(yōu)異的熱熔膠和高的收縮比提供了優(yōu)異的密封

? 用于電子連接部分應(yīng)用的密封和絕緣保護(hù)

? 不需要移開(kāi)連接器就可以方便修補(bǔ)損傷的絕緣層

? 可選用EVA熱熔膠或聚酰胺(PA)熱熔膠

? 高收縮比3:1、4:1可用作非規(guī)則形狀物件的絕緣和密封保護(hù)

? 柔軟、阻燃

? 符合ROHS、REACH等環(huán)保規(guī)范

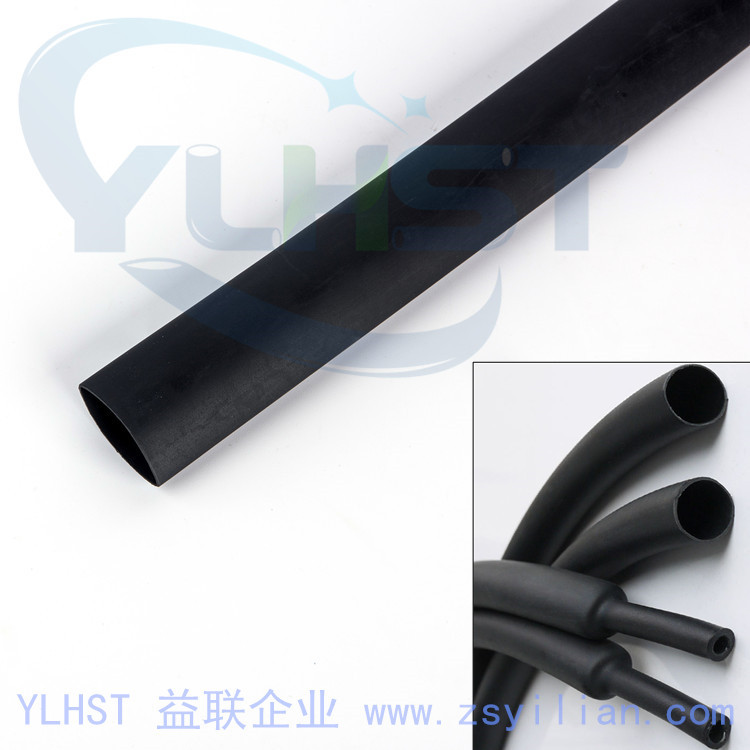

顏色

? 標(biāo)準(zhǔn)顏色:黑色

? 其他顏色可訂制

操作溫度范圍

? 連續(xù)使用溫度范圍:-55℃~125℃

? {zd1}起始收縮溫度:80℃

? {zd1}wq收縮溫度:110℃

符合標(biāo)準(zhǔn)

? SAE AMS-DTL-23053/4

? UL224 E360866 125℃ 600V

性能指標(biāo)

|

性能

|

指標(biāo)要求

|

測(cè)試方法

|

典型值

|

|

縱向收縮率

|

≤10%

|

ASTM D 2671

|

≤5%

|

|

抗張強(qiáng)度

|

10.3MPa min

|

ASTM D 638

|

≥12MPa

|

|

斷裂伸長(zhǎng)率

|

200% min

|

ASTM D 638

|

≥400%

|

|

老化后抗張強(qiáng)度

(熱老化158℃,168小時(shí))

|

初始值的70%以上

|

ASTM D 638

|

≥90%

|

|

老化后斷裂伸長(zhǎng)率(158℃,168hrs)

|

100% min

|

ASTM D 638

|

≥300%

|

|

熱沖擊

|

無(wú)裂紋

|

ASTM D 2671

|

無(wú)裂紋

|

|

低溫柔軟性

(-55℃,4小時(shí))

|

無(wú)裂紋

|

ASTM D 2671

|

無(wú)裂紋

|

|

絕緣耐壓和擊穿

|

2500V,60sec,不擊穿

|

ASTM D 2671

|

不擊穿

|

|

體積電阻率

|

1014??cm min

|

ASTM D 638

|

≥1014??cm

|

|

銅腐性

|

無(wú)腐蝕

|

ASTM D 2671

|

無(wú)腐蝕

|

|

阻燃性

|

ALL TUBING FLAME TEST

|

UL224

|

通過(guò)

|

規(guī)格尺寸

|

規(guī)格

|

收縮前(mm)

|

收縮后(mm)

|

標(biāo)準(zhǔn)包裝(m/條或m/卷)

|

|

內(nèi)徑(min)

|

內(nèi)徑(max)

|

壁厚

|

膠厚

|

|

3:1(inch,mm)

|

|

1/8(3/1)

|

3.0

|

1.0

|

1.00+0.28

|

0.50

|

1.22/200

|

|

3/6(4.8/1.6)

|

4.8

|

1.6

|

1.00+0.28

|

0.50

|

1.22/100

|

|

1/4(6/2)

|

6.0

|

2.0

|

1.00+0.28

|

0.50

|

1.22/100

|

|

3/8(9/3)

|

9.0

|

3.0

|

1.40+0.28

|

0.60

|

1.22/50

|

|

1/2(12/4)

|

12.0

|

4.0

|

1.78+0.38

|

0.76

|

1.22/25

|

|

3/4(18/6)

|

18.0

|

6.0

|

2.25+0.55

|

0.76

|

1.22/25

|

|

1(24/8)

|

24.0

|

8.0

|

2.54+0.55

|

1.02

|

1.22/25

|

|

11/2(39/13)

|

39.0

|

13.0

|

2.54+0.55

|

1.02

|

1.22/25

|

|

4:1(mm)

|

|

4/1

|

4.0

|

1.0

|

1.00+0.28

|

0.50

|

1.22/100

|

|

8/2

|

8.0

|

2.0

|

1.00+0.28

|

0.50

|

1.22/50

|

|

12/3

|

12.0

|

3.0

|

1.40+0.28

|

0.60

|

1.22/25

|

|

16/4

|

16.0

|

4.0

|

1.78+0.38

|

0.76

|

1.22/25

|

|

24/6

|

24.0

|

6.0

|

2.25+0.55

|

0.76

|

1.22/25

|

|

32/8

|

32.0

|

8.0

|

2.54+0.55

|

1.02

|

1.22/25

|

|

52/13

|

52.0

|

13.0

|

2.54+0.55

|

1.02

|

1.22

|

壁厚包含膠厚

其他規(guī)格尺寸可定制

DW125 Soft And High Times Double Wall Heat Shrinkable Sleeve

Application

Dual-wall adhesive-lined heat shrinkable tubing is made by co-extrusion of excellent polyolefin compounds and hot-melt adhesive. It is used for water-proofing and insulation protection of wire and cable and wire harnesses, and connector-to-cable transitions. It is typically used in the insulation and sealing of electrical and electronic components, automotive and communication industry.

Characteristics

v Good hot-melt adhesive and high expansion ratio to provide good sealing protection.

v Environmental sealing and protection of electrical applications.

v Conveniently repair most damaged cable jackets without removing connectors.

v EVA hot melt adhesive or PA adhesive are available.

v High Shrink ratio 3:1 and 4:1 allows for insulation and sealing of irregular shapes.

v Flexible, flame retardant

v ROHS and REACH compliant

Color

v Standard color: Black

v Other colors are available upon request.

Operating Temperature Range

v Operating temperature: -55℃~125℃

v Minimum shrink temperature: 80℃

v Minimum fully recovery temperature: 110℃

Approvals

v SAE AMS-DTL-23053/4

v UL224 E360866 125℃ 600V

Property

|

Property

|

Requirement

|

Test method

|

Typical data

|

|

Longitudinal shrinkage

|

≤10%

|

ASTM D 2671

|

≤5%

|

|

Tensile strength

|

10.3MPa min

|

ASTM D 638

|

≥12MPa

|

|

Elongation at break

|

200% min

|

ASTM D 638

|

≥400%

|

|

Tensile strength after aging

(158℃,168hrs)

|

70% of original

|

ASTM D 638

|

≥90%

|

|

Elongation after aging

(158℃,168hrs)

|

100% min

|

ASTM D 638

|

≥300%

|

|

Heat shock

|

No crack

|

ASTM D 2671

|

No crack

|

|

Low-temperature flexibility(-55℃,4hrs)

|

No crack

|

ASTM D 2671

|

No crack

|

|

Dielectric voltage withstand

|

2500V,60sec,no breakdown

|

ASTM D 2671

|

No breakdown

|

|

Volume resistivity

|

1014??cm min

|

ASTM D 638

|

≥1014??cm

|

|

Copper corrosion

|

No corrosion

|

ASTM D 2671

|

No corrosion

|

|

Flammability

|

ALL TUBING FLAME TEST

|

UL224

|

Pass

|

Sizes

|

Size

|

As supplied

(mm)

|

After recovered(mm)

|

Standard packing

(m/pc,m/roll)

|

|

Inside diameter

(min)

|

Inside diameter

(max)

|

Wall thickness

|

Adhesive thickness

(nominal)

|

|

3:1(inch,mm)

|

|

1/8(3/1)

|

3.0

|

1.0

|

1.00+0.28

|

0.50

|

1.22/200

|

|

3/6(4.8/1.6)

|

4.8

|

1.6

|

1.00+0.28

|

0.50

|

1.22/100

|

|

1/4(6/2)

|

6.0

|

2.0

|

1.00+0.28

|

0.50

|

1.22/100

|

|

3/8(9/3)

|

9.0

|

3.0

|

1.40+0.28

|

0.60

|

1.22/50

|

|

1/2(12/4)

|

12.0

|

4.0

|

1.78+0.38

|

0.76

|

1.22/25

|

|

3/4(18/6)

|

18.0

|

6.0

|

2.25+0.55

|

0.76

|

1.22/25

|

|

1(24/8)

|

24.0

|

8.0

|

2.54+0.55

|

1.02

|

1.22/25

|

|

11/2(39/13)

|

39.0

|

13.0

|

2.54+0.55

|

1.02

|

1.22/25

|

|

4:1(mm)

|

|

4/1

|

4.0

|

1.0

|

1.00+0.28

|

0.50

|

1.22/100

|

|

8/2

|

8.0

|

2.0

|

1.00+0.28

|

0.50

|

1.22/50

|

|

12/3

|

12.0

|

3.0

|

1.40+0.28

|

0.60

|

1.22/25

|

|

16/4

|

16.0

|

4.0

|

1.78+0.38

|

0.76

|

1.22/25

|

|

24/6

|

24.0

|

6.0

|

2.25+0.55

|

0.76

|

1.22/25

|

|

32/8

|

32.0

|

8.0

|

2.54+0.55

|

1.02

|

1.22/25

|

|

52/13

|

52.0

|

13.0

|

2.54+0.55

|

1.02

|

1.22

|

Wall thickness includes adhesive thickness.

Other sizes are available upon request.