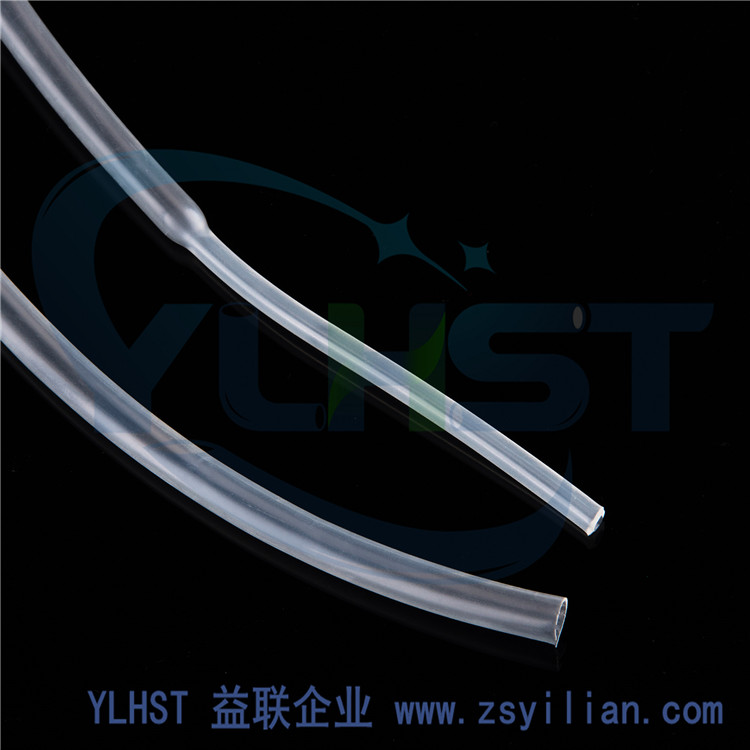

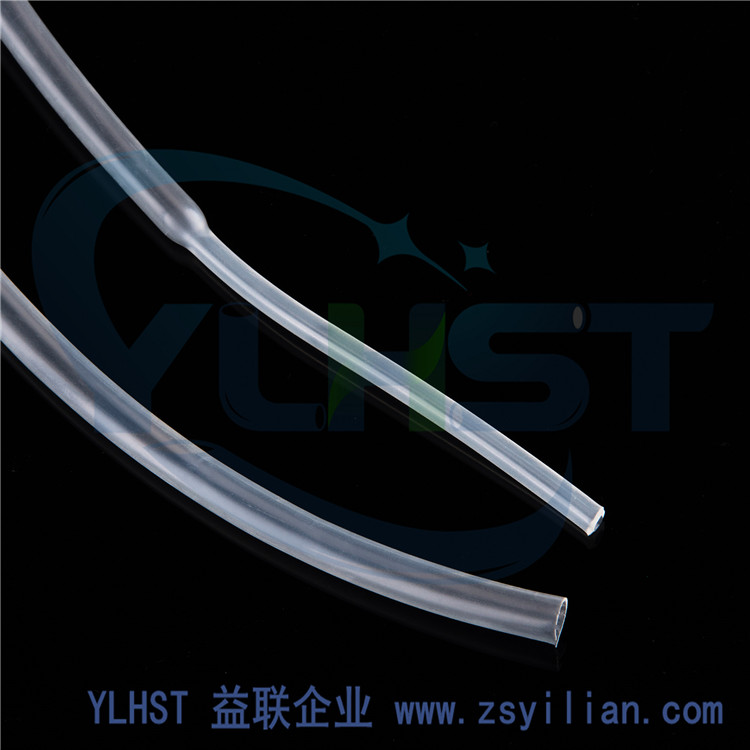

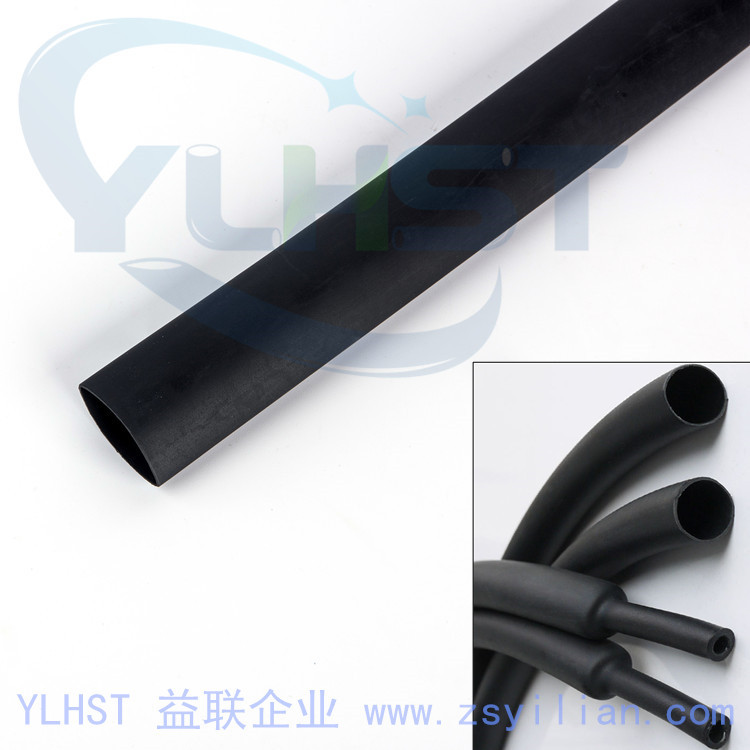

DWFL wq阻燃高收縮比雙壁熱縮管

應用

由阻燃聚烯烴和阻燃熱熔膠共擠制造而成,可為{sx}或規定wq阻燃性的應用提供{zj0}解決方案。適合用于汽車配線市場和其他嚴苛環境。高收縮比可以對較大范圍的元器件提供極好的環境保護。可以很好地應用于電子電器、汽車、通訊、航天、軍工等很多行業中。

特性

v 高收縮比:4:1

v 外層阻燃聚烯烴和內層阻燃熱熔膠提供了wq阻燃性

v 優異的熱熔膠提供了優異的環境密封保護

v 優異的機械性能、化學性能和電性能

v 可應用于范圍廣泛的線纜、端子和部件

v 符合ROHS、REACH等環保規范

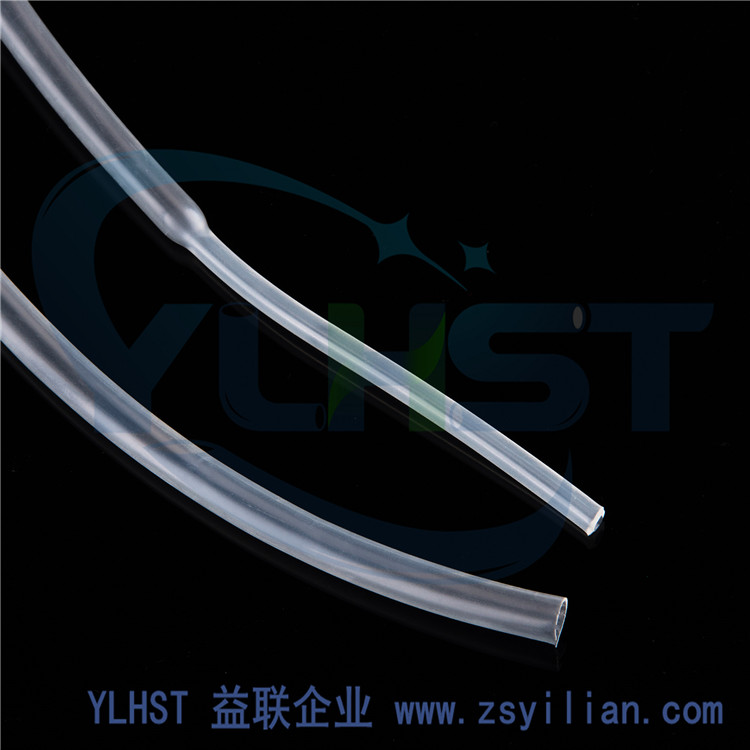

顏色

v 標準顏色:黑色,內層白色熱熔膠

v 其他顏色可定制

操作溫度范圍

v 連續使用溫度:-44℃~135℃

v {zd1}起始收縮溫度:110℃

v {zd1}wq收縮溫度:135℃

符合標準

v SAE AMS-DTL-23053/4,Class 3

v UL224 125℃ 600V

性能指標

|

性能

|

指標要求

|

測試方法

|

典型值

|

|

縱向收縮率

|

≤10%

|

ASTM D 2671

|

≤5%

|

|

抗張強度

|

10.3MPa min

|

ASTM D 638

|

≥12MPa

|

|

斷裂伸長率

|

200% min

|

ASTM D 638

|

≥400%

|

|

老化后斷裂伸長率

(熱老化175℃,168小時)

|

100% min

|

ASTM D 638

|

≥300%

|

|

熱沖擊

|

無裂紋

|

ASTM D 2671

|

無裂紋

|

|

低溫柔軟性

(-55℃,4小時)

|

無裂紋

|

ASTM D 2671

|

無裂紋

|

|

絕緣耐壓和擊穿

|

2500V,60sec,不擊穿

|

ASTM D 2671

|

不擊穿

|

|

體積電阻率

|

1014??cm min

|

ASTM D 876

|

≥1014??cm

|

|

銅腐性

|

無腐蝕

|

ASTM D 2671

|

無腐蝕

|

|

阻燃性

|

VW-1

|

UL224

|

通過

|

規格尺寸

|

規格

|

收縮前(mm)

|

收縮后(mm)

|

標準包裝

(m/條)

|

|

內徑(min)

|

內徑(max)

|

壁厚

|

膠厚

|

|

Ф7.62

|

7.62

|

1.65

|

1.52+0.30

|

0.71

|

1.22

|

|

Ф9.02

|

9.02

|

2.29

|

1.52+0.30

|

0.71

|

1.22

|

|

Ф11.56

|

11.56

|

2.54

|

2.29+0.30

|

1.32

|

1.22

|

|

Ф17.79

|

17.79

|

4.45

|

2.54+0.30

|

1.35

|

1.22

|

壁厚包含膠厚

其他規格尺寸可定制

DWFL Fully flame-retardant Dual-wall Heat Shrinkable Polyolefin Tubing

Application

DWFL fully flame-retardant dual-wall adhesive-lined heat shrinkable tubing is made by co-extrusion of excellent flame-retardant polyolefin compound and flame-retardant hot-melt adhesive to provide the optimum solution for applications where full retardancy is preferred, or specified. It is suitable for use in the automotive harness market and other harsh environments. DWFL has high shrink ratio to meet most component sealing requirements, and is compatible with a wide range of application equipment. It is typical used in the insulation and sealing of electrical and electronic components, automotive, communication, aerospace and military industry.

Characteristics

v High shrink ratio: 4:1

v Outer flame-retardant polyolefin and flame-retardant adhesive provide full flame retardancy.

v Excellent hot-melt adhesive provides good environmental sealing protection.

v Excellent mechanical, chemical and electrical properties.

v Suitable for a wide range of dimensions of wire, connectors and components.

v ROHS and REACH compliant

Color

v Standard color: black with white inner adhesive

v Other colors are available upon request.

Operating Temperature Range

v Operating temperature: -40℃~135℃

v Minimum shrink temperature: 110℃

v Minimum fully recovery temperature: 135℃

Approvals

v SAE AMS-DTL-23053/4,Class 3

v UL224 125℃ 600V

Property

|

Property

|

Requirement

|

Test method

|

Typical data

|

|

Longitudinal shrinkage

|

≤10%

|

ASTM D 2671

|

≤5%

|

|

Tensile strength

|

10.3MPa min

|

ASTM D 638

|

≥12MPa

|

|

Elongation at break

|

200% min

|

ASTM D 638

|

≥400%

|

|

Elongation after aging

(175℃,168hrs)

|

100% min

|

ASTM D 638

|

≥300%

|

|

Heat shock

|

No crack

|

ASTM D 2671

|

No crack

|

|

Low-temperature flexibility(-55℃,4hrs)

|

No crack

|

ASTM D 2671

|

No crack

|

|

Dielectric voltage withstand

|

2500V,60sec,no breakdown

|

ASTM D 2671

|

No breakdown

|

|

Volume resistivity

|

1014??cm min

|

ASTM D 876

|

≥1014??cm

|

|

Copper corrosion

|

No corrosion

|

ASTM D 2671

|

No corrosion

|

|

Flammability

|

VW-1

|

UL224

|

Pass

|

Sizes

|

Size

|

As supplied

(mm)

|

After recovered(mm)

|

Standard packing

(m/pc,m/roll)

|

|

Inside diameter

(min)

|

Inside diameter

(max)

|

Wall thickness

|

Adhesive thickness

(nominal)

|

|

Ф7.62

|

7.62

|

1.65

|

1.52+0.30

|

0.71

|

1.22

|

|

Ф9.02

|

9.02

|

2.29

|

1.52+0.30

|

0.71

|

1.22

|

|

Ф11.56

|

11.56

|

2.54

|

2.29+0.30

|

1.32

|

1.22

|

|

Ф17.79

|

17.79

|

4.45

|

2.54+0.30

|

1.35

|

1.22

|

Wall thickness includes adhesive thickness.

Other sizes are available upon request.