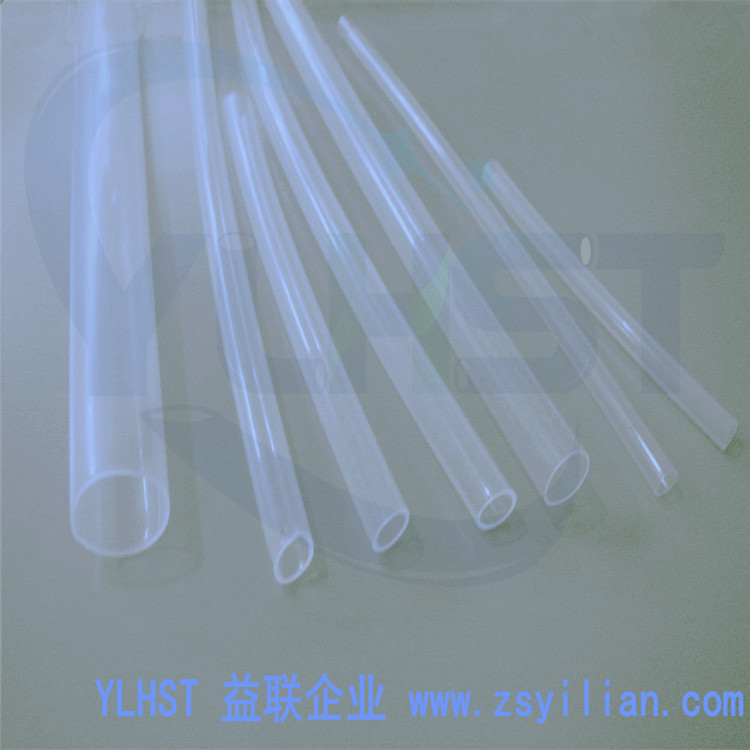

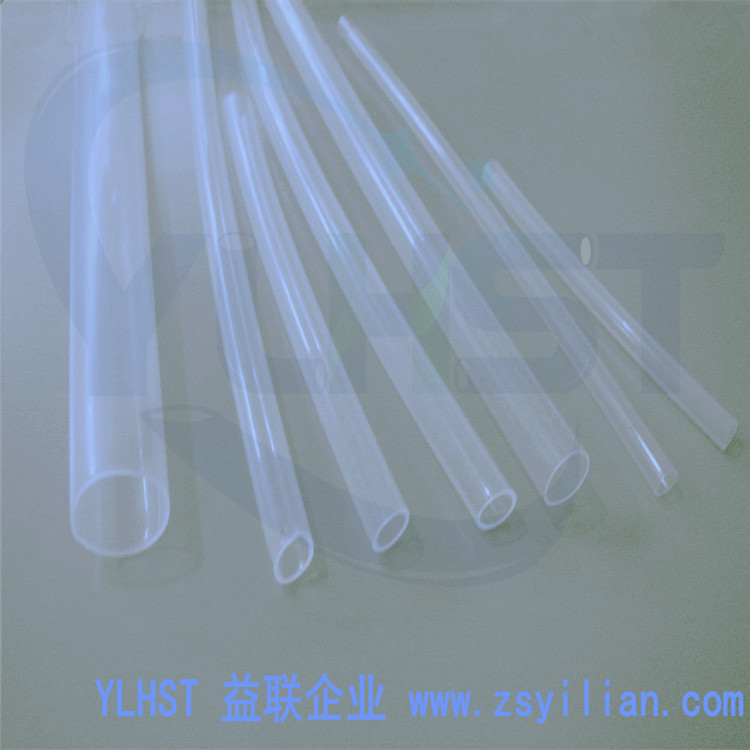

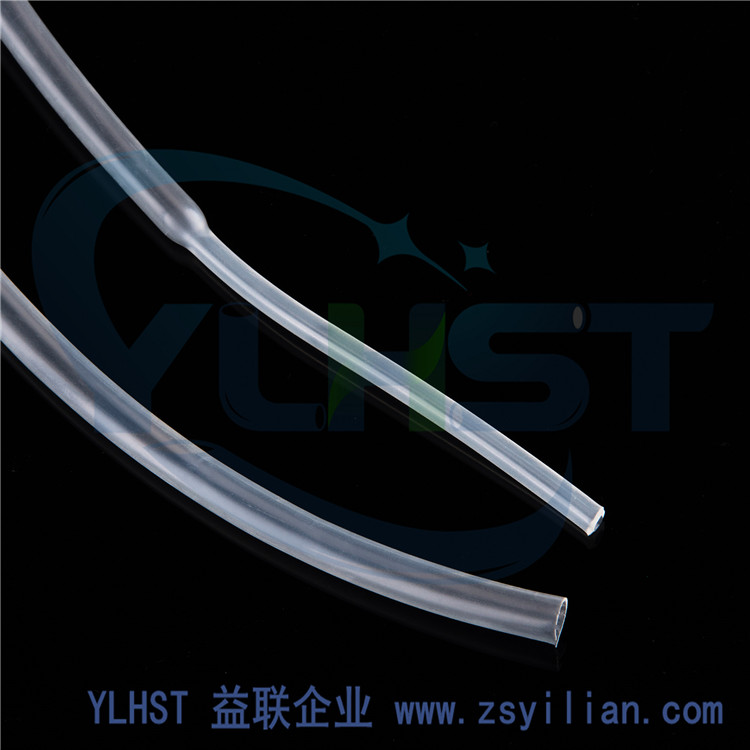

PFA 耐溫260℃PFA收縮套管

應用

由可溶性聚四氟乙烯(PFA)材料制成,具有耐高溫(260℃)、耐腐蝕、高絕緣、機械強度佳等特性,比PTFE熱縮管具有優異的透明度。其廣泛用于電子、計算機、電熱、航天、軍事、通訊等重要科技工業。

特性

v 收縮比:1.25:1

v 優異的的透明度

v 高阻燃

v 耐高溫260℃

v 優異的機械性能和耐化學腐蝕性能

v 符合ROHS、REACH等環保規范

v 顏色

v 標準顏色:透明

操作溫度范圍

v 連續使用溫度:-65℃~260℃

v {zd1}wq收縮溫度:350℃

性能指標

|

性能

|

指標要求

|

測試方法

|

典型值

|

|

縱向收縮率

|

≤5%

|

ASTM D 2671

|

≤3%

|

|

抗張強度

|

17.3MPa min

|

ASTM D 638

|

≥25MPa

|

|

斷裂伸長率

|

200% min

|

ASTM D 638

|

≥300%

|

|

絕緣耐壓和擊穿

|

2500V,60sec,不擊穿

|

ASTM D 2671

|

通過

|

|

體積電阻率

|

1015??cm min

|

ASTM D 876

|

≥1016??cm

|

|

腐蝕性

|

無腐蝕

|

ASTM D 2671

|

無腐蝕

|

|

阻燃性

|

VW-1

|

UL224

|

通過

|

|

介電常數

|

|

|

2.1

|

|

摩擦系數

|

|

|

0.1-0.2

|

規格尺寸

|

規格

|

收縮前(mm)

|

wq收縮后(mm)

|

標準包裝

(m/條)

|

|

內徑(min)

|

內徑(max)

|

壁厚

|

|

Ф7

|

7.0

|

5.7

|

0.25+0.05

|

1.0

|

|

Ф11.5

|

11.5

|

9.3

|

0.35+0.05

|

1.0

|

|

Ф14.5

|

14.5

|

11.7

|

0.35+0.05

|

1.0

|

|

Ф19

|

19.0

|

15.3

|

0.35+0.05

|

1.0

|

|

Ф24

|

24.0

|

19.3

|

0.50+0.10

|

1.0

|

|

Ф28

|

28.0

|

22.5

|

0.50+0.10

|

1.0

|

|

Ф35

|

35.0

|

28.1

|

0.50+0.10

|

1.0

|

|

Ф44

|

44.0

|

36.1

|

0.50+0.10

|

1.0

|

|

Ф54

|

54.0

|

43.3

|

0.50+0.10

|

1.0

|

|

Ф66

|

66.0

|

52.9

|

0.50+0.10

|

1.0

|

|

Ф78

|

78.0

|

62.5

|

0.50+0.10

|

1.0

|

|

Ф90

|

90.0

|

72.1

|

0.50+0.10

|

1.0

|

|

Ф103

|

103

|

82.5

|

0.50+0.10

|

1.0

|

其他規格尺寸可定制

PFA 260℃ Temperature Resistant PFA Heat Shrinkable Tubing

Application

PFA heat shrinkable tubing is made of PFA with excellent high-temperature performance, chemical resistance, high insulation and excellent mechanical properties. Designed to provide insulation and mechanical protection in severe chemical and thermal environments. Widely used in electronic, aerospace, military and communication fields. Compared to PTFE tubing, PFA has excellent clarity.

Characteristics

v Shrink ratio: 1.25:1

v Excellent clarity

v High flame resistance

v High temperature resistant to 260℃

v Superior physical and chemical properties.

v ROHS and REACH compliant.

Color

v Standard color: Clear

Operating Temperature Range

v Operating temperature: -65℃~260℃

v Minimum fully recovery temperature: 350℃

Property

|

Property

|

Requirement

|

Test method

|

Typical data

|

|

Longitudinal shrinkage

|

≤5%

|

ASTM D 2671

|

≤3%

|

|

Tensile strength

|

17.3MPa min

|

ASTM D 638

|

≥25MPa

|

|

Elongation at break

|

200% min

|

ASTM D 638

|

≥300%

|

|

Dielectric voltage withstand

|

2500V,60sec,no breakdown

|

ASTM D 2671

|

Pass

|

|

Volume resistivity

|

1015??cm min

|

ASTM D 876

|

≥1016??cm

|

|

Copper corrosion

|

No corrosion

|

ASTM D 2671

|

No corrosion

|

|

Flammability

|

VW-1

|

UL224

|

Pass

|

|

Dielectric constant

|

|

|

2.1

|

|

Friction coefficient

|

|

|

0.1-0.2

|

Sizes

|

Size

|

As supplied(mm)

|

After recovered(mm)

|

Standard packing(m/pc)

|

|

Inside diameter(min)

|

Inside diameter(max)

|

Wall thickness

|

|

Ф7

|

7.0

|

5.7

|

0.25+0.05

|

1.0

|

|

Ф11.5

|

11.5

|

9.3

|

0.35+0.05

|

1.0

|

|

Ф14.5

|

14.5

|

11.7

|

0.35+0.05

|

1.0

|

|

Ф19

|

19.0

|

15.3

|

0.35+0.05

|

1.0

|

|

Ф24

|

24.0

|

19.3

|

0.50+0.10

|

1.0

|

|

Ф28

|

28.0

|

22.5

|

0.50+0.10

|

1.0

|

|

Ф35

|

35.0

|

28.1

|

0.50+0.10

|

1.0

|

|

Ф44

|

44.0

|

36.1

|

0.50+0.10

|

1.0

|

|

Ф54

|

54.0

|

43.3

|

0.50+0.10

|

1.0

|

|

Ф66

|

66.0

|

52.9

|

0.50+0.10

|

1.0

|

|

Ф78

|

78.0

|

62.5

|

0.50+0.10

|

1.0

|

|

Ф90

|

90.0

|

72.1

|

0.50+0.10

|

1.0

|

|

Ф103

|

103

|

82.5

|

0.50+0.10

|

1.0

|

Other sizes are available upon request.