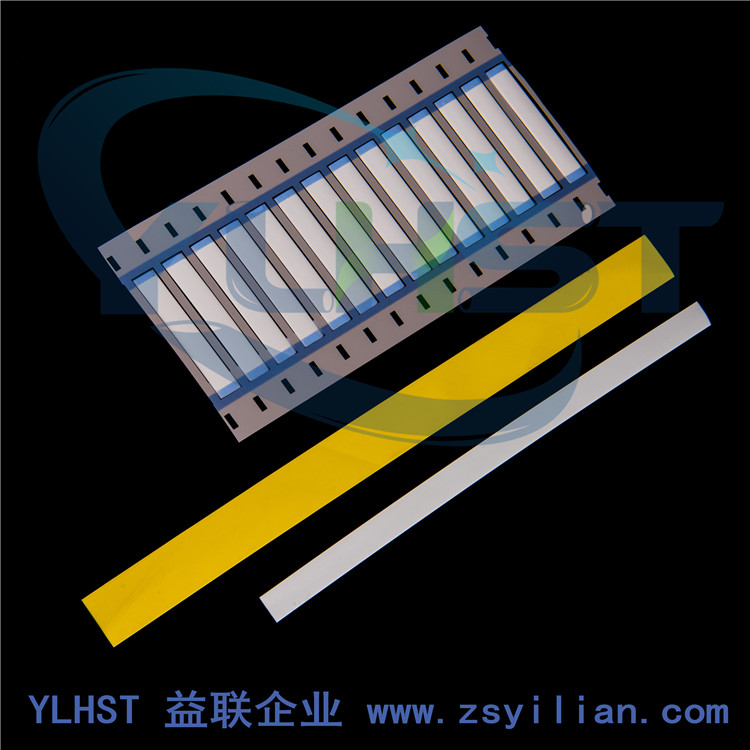

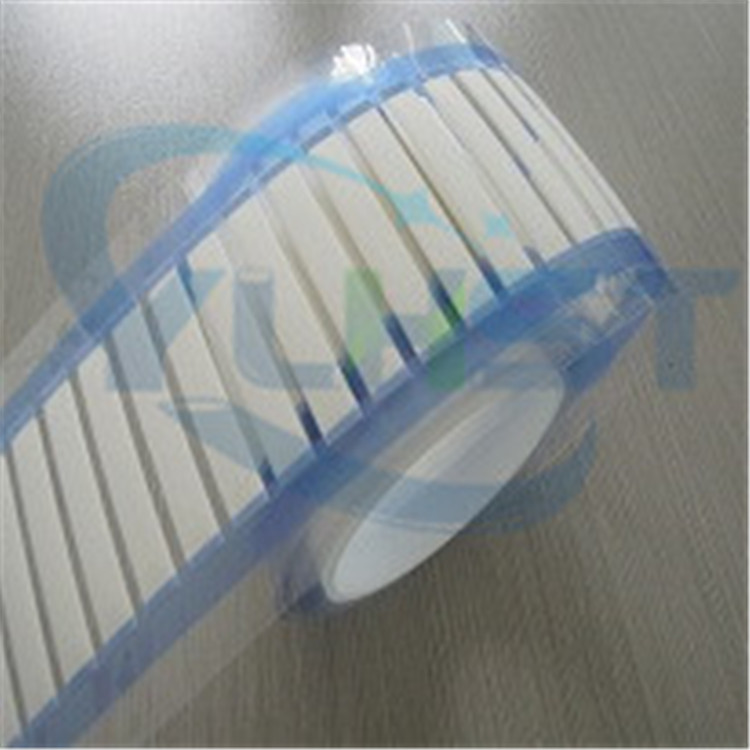

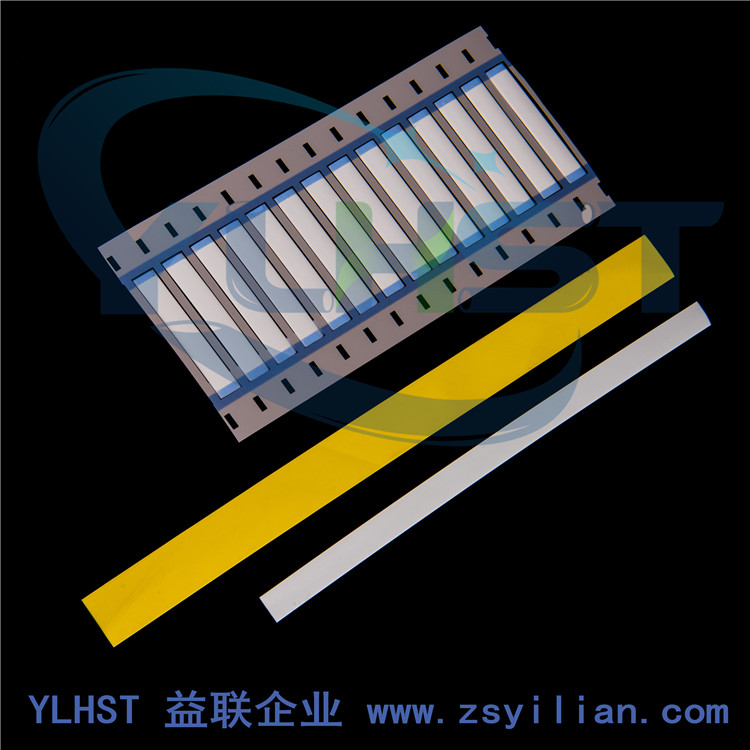

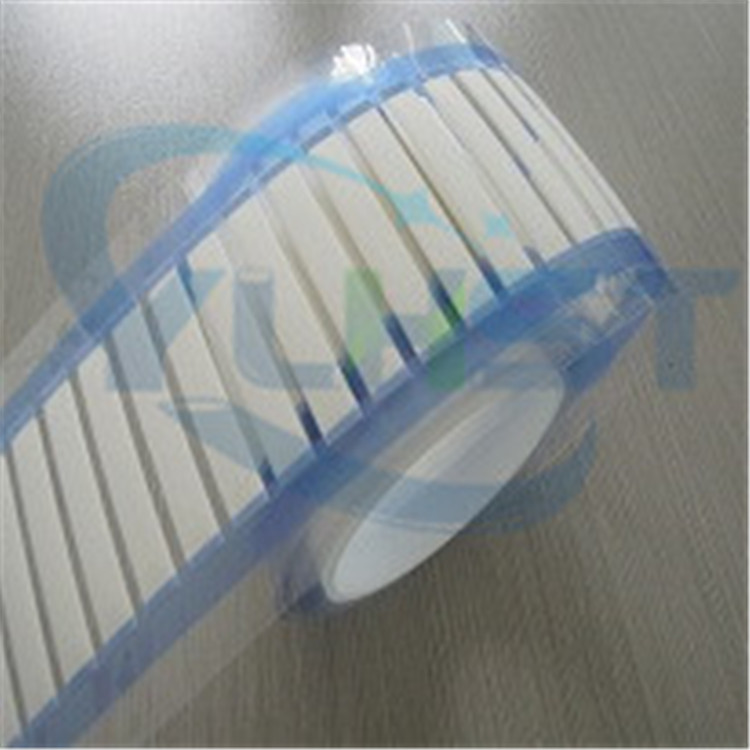

HT225 軍標級耐高溫熱收縮標識套管

應用

是專為耐高溫高性能電線電纜標識而設計,由輻照交聯優質耐溫225℃含氟聚合物材質制成,具有優異的耐高低溫性能、阻燃性能、電氣性能、物理性能、化學性能和打印性能,方便提供給標識打印機直接打印,標識持久,適用于耐高溫線束、線纜的高性能持久標識。

特性

v 收縮比:2:1

v 軍標級

v 耐高溫連續使用上

v 優異的打印性能,持久標識。

v 高阻燃性

v 優異的抗液體性能

v 優異的電絕緣性能、物理性能和化學性能

v 符合ROHS、REACH環保規范

顏色

v 標準顏色:白色、黃色

v 其他顏色可定制

操作溫度范圍

v 連續使用溫度范圍:-55℃~225℃

v {zd1}起始收縮溫度:135℃

v {zd1}wq收縮溫度:200℃

符合標準

v SAE AS 81531

v MIL-STD-202

性能指標

|

性能

|

指標要求

|

測試方法

|

典型值

|

|

縱向收縮率

|

≤10%

|

ASTM D 2671

|

≤5%

|

|

抗張強度

|

17.3MPa min

|

ASTM D 638

|

≥24MPa

|

|

斷裂伸長率

|

200% min

|

ASTM D 638

|

≥300%

|

|

老化后斷裂伸長率

(熱老化225℃,168小時)

|

100% min

|

ASTM D 638

|

≥200%

|

|

熱沖擊

(275℃,4小時)

|

無裂紋

|

ASTM D 2671

|

無裂紋

|

|

低溫柔軟性

(-55℃,4小時)

|

無裂紋

|

ASTM D 2671

|

無裂紋

|

|

絕緣耐壓和擊穿

|

2500V,60sec,不擊穿

|

ASTM D 2671

|

不擊穿

|

|

體積電阻率

|

1011??cm min

|

ASTM D 876

|

≥1012??cm

|

|

腐蝕性

|

無腐蝕

|

ASTM D 2671

|

通過

|

|

阻燃性

|

15分鐘內自熄

|

ASM-DTL-23053

|

通過

|

|

打印性能

|

100次橡皮擦,可辨認

100次來回擦,可辨認

|

SAE SA81531

MIL-STD-202

|

通過

|

|

抗液體

(23℃,24小時)

|

打印吸識別

|

AS81531

|

通過

|

規格尺寸

|

規格

|

收縮前(mm)

|

wq收縮后(mm)

|

適用線纜范圍(mm)

|

|

英制

|

公制

|

內徑(min)

|

內徑(max)

|

|

3/32

|

Ф2.4

|

2.4

|

0.8

|

0.8-2.0

|

|

1/8

|

Ф3.2

|

3.2

|

1.6

|

1.7-2.7

|

|

3/16

|

Ф4.8

|

4.8

|

2.4

|

2.5-4.5

|

|

1/4

|

Ф6.4

|

6.4

|

3.2

|

3.4-6.0

|

|

3/8

|

Ф9.5

|

9.5

|

4.8

|

5.0-9.0

|

|

1/2

|

Ф12.7

|

12.7

|

6.4

|

6.6-12.0

|

|

3/4

|

Ф19.1

|

19.1

|

9.5

|

9.9-18.5

|

|

1

|

Ф25.4

|

25.4

|

12.7

|

13.0-24.5

|

|

11/2

|

Ф38.1

|

38.1

|

19.1

|

21.0-37.0

|

|

2

|

Ф50.8

|

50.8

|

25.4

|

27.0-48.0

|

其他規格尺寸可定制

HT225 Military Grade High-temperature Resistant Heat Shrinkable Identification Sleeve

Application

Special designed to meet the requirement of high performance identification of wire and cable in high temperature applications or where extreme resistance to fuels, lubricants applications solvent is required. It is made of special fluoropolymer with excellent high-temperature performance, highly flame retardant, excellent electrical, physical, chemical properties and permanent printing properties. Widely used in high-temperature permanent identification in industry, military, areospace, etc.

Characteristics

v Shrink ratio: 2:1

v Military grade

v High continuous operating temperature

v Excellent printing property, permanent identification

v Highly flame-retardance

v Excellent fluids resistance

v Excellent electrical, physical, chemical and printing properties.

v ROHS and REACH compliant

Color

v Standard color: White(-9), yellow(-4)

v Other colors are available upon request.

Operating Temperature Range

v Operating temperature: -55℃~225℃

v Minimum shrink temperature: 135℃

v Minimum fully recovery temperature: 200℃

Approvals

v SAE AS 81531

v MIL-STD-202

Property

|

Property

|

Requirement

|

Test method

|

Typical data

|

|

Longitudinal shrinkage

|

≤10%

|

ASTM D 2671

|

≤5%

|

|

Tensile strength

|

17.3MPa min

|

ASTM D 638

|

≥24MPa

|

|

Elongation at break

|

200% min

|

ASTM D 638

|

≥300%

|

|

Elongation after aging

(225℃,168hrs)

|

100% min

|

ASTM D 638

|

≥200%

|

|

Heat shock

(275℃,4hrs)

|

No crack

|

ASTM D 2671

|

No crack

|

|

Low-temperature flexibility(-55℃,4hrs)

|

No crack

|

ASTM D 2671

|

No crack

|

|

Dielectric voltage withstand

|

2500V,60sec,no breakdown

|

ASTM D 2671

|

No breakdown

|

|

Volume resistivity

|

1011??cm min

|

ASTM D 876

|

≥1012??cm

|

|

Copper corrosion

|

No corrosion

|

ASTM D 2671

|

Pass

|

|

Flammability

|

Self-extinguishing within 15 seconds

|

ASM-DTL-23053

|

Pass

|

|

Printing performance

|

100rubs, legible

100strokes, legible

|

SAE SA81531

MIL-STD-202

|

Pass

|

|

Fluid resistance(23℃,24hrs)

|

Printing legible

|

AS81531

|

Pass

|

Sizes

|

Size

|

As supplied (mm)

|

After recovered(mm)

|

Recommended

use range

(mm)

|

|

inch

|

mm

|

Inside diameter(min)

|

Inside diameter (max)

|

|

3/32

|

Ф2.4

|

2.4

|

0.8

|

0.8-2.0

|

|

1/8

|

Ф3.2

|

3.2

|

1.6

|

1.7-2.7

|

|

3/16

|

Ф4.8

|

4.8

|

2.4

|

2.5-4.5

|

|

1/4

|

Ф6.4

|

6.4

|

3.2

|

3.4-6.0

|

|

3/8

|

Ф9.5

|

9.5

|

4.8

|

5.0-9.0

|

|

1/2

|

Ф12.7

|

12.7

|

6.4

|

6.6-12.0

|

|

3/4

|

Ф19.1

|

19.1

|

9.5

|

9.9-18.5

|

|

1

|

Ф25.4

|

25.4

|

12.7

|

13.0-24.5

|

|

11/2

|

Ф38.1

|

38.1

|

19.1

|

21.0-37.0

|

|

2

|

Ф50.8

|

50.8

|

25.4

|

27.0-48.0

|

Other sizes are available upon request.